Epoxy Flooring: The Ultimate Guide for Durable, High-Performance Industrial Floors

Industrial facilities face constant challenges with floor durability, chemical spills, and heavy equipment wear. Epoxy flooring delivers a proven solution that transforms concrete surfaces into resilient, long-lasting industrial floors capable of handling the toughest conditions.

This comprehensive guide targets facility managers, plant engineers, warehouse operators, and business owners who need reliable flooring solutions for manufacturing plants, warehouses, automotive shops, and commercial kitchens. You'll discover how industrial epoxy flooring outperforms traditional options while reducing long-term costs.

We'll walk you through the key benefits that make epoxy floor coating the smart choice for high-traffic environments, including superior chemical resistance and easy maintenance. You'll also learn how to select the right epoxy system for your specific needs and understand the professional installation process that ensures optimal performance. Plus, we'll cover practical maintenance strategies and provide a detailed cost analysis that demonstrates why investing in quality epoxy flooring services pays off over time.

Understanding Epoxy Flooring Fundamentals

What Makes Epoxy Flooring Superior to Traditional Options

Epoxy flooring stands out from traditional flooring solutions because it creates a seamless, non-porous surface that can withstand the toughest industrial demands. Unlike concrete floors that crack and deteriorate under heavy machinery, or vinyl tiles that peel and collect dirt in seams, epoxy floor coating bonds directly to the substrate at a molecular level.

Traditional concrete floors are porous, which means they absorb oils, chemicals, and moisture. This absorption leads to staining, bacterial growth, and structural weakening over time. Epoxy flooring eliminates these problems by creating an impermeable barrier that repels liquids and resists chemical attack.

The seamless nature of epoxy flooring means there are no joints, cracks, or seams where bacteria can hide or contaminants can accumulate. This makes cleaning incredibly simple – a quick mop or pressure wash restores the floor to pristine condition. Traditional flooring options like tile or vinyl require extensive maintenance around grout lines and seams, creating ongoing labor costs.

Durability is where epoxy truly shines. While traditional floors may last 5-10 years under industrial conditions, properly installed epoxy systems can perform for 15-20 years or more. The material resists impact damage, abrasion from heavy traffic, and chemical spills that would destroy conventional flooring materials.

Key Components and Chemical Properties That Deliver Performance

Industrial epoxy flooring systems consist of two main components: epoxy resin and a hardening agent (curing agent). When these components mix, they undergo a chemical reaction called cross-linking, which creates an incredibly strong, three-dimensional polymer network.

The epoxy resin provides the base properties of the system. Most industrial applications use bisphenol-A epoxy resins, which offer excellent adhesion, chemical resistance, and mechanical properties. Specialty resins like novolac epoxy deliver enhanced chemical resistance for environments with aggressive solvents or acids.

Curing agents determine many of the final properties of the cured epoxy. Amine-based hardeners are common for room temperature curing and provide good chemical resistance. Polyamide hardeners offer better flexibility and impact resistance, making them ideal for areas subject to thermal cycling or vibration.

Additives play a crucial role in customizing performance. Silica aggregates increase slip resistance and add texture. Glass microspheres reduce weight while maintaining strength. Conductive additives create static-dissipative properties for electronics manufacturing. UV-stable additives prevent yellowing and degradation from sunlight exposure.

The cross-linking process creates covalent bonds between polymer chains, resulting in a material that's harder and more chemically resistant than either component alone. This network structure explains why cured epoxy can't be melted or dissolved by most solvents – the entire floor essentially becomes one giant molecule.

Different Types of Epoxy Systems for Industrial Applications

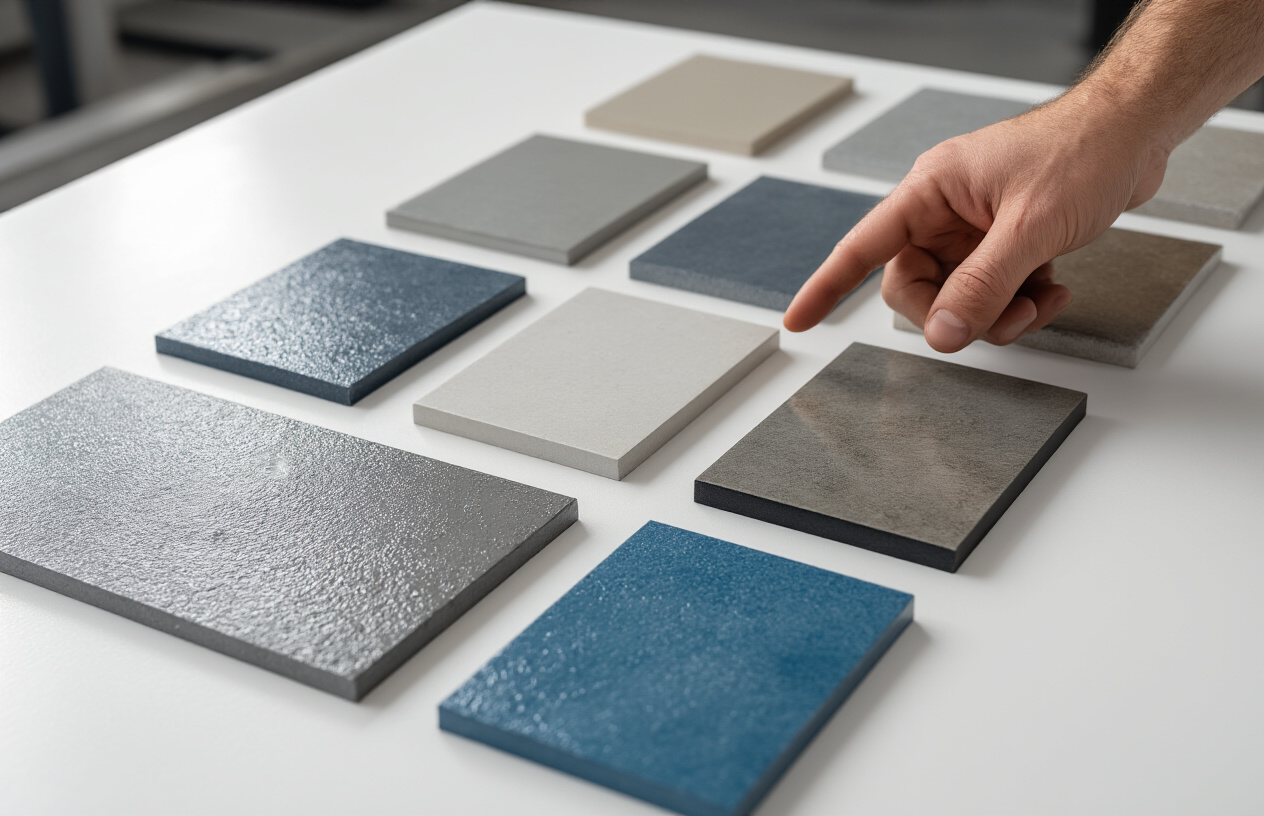

Epoxy flooring services typically offer several system types, each engineered for specific performance requirements and environmental conditions.

Self-Leveling Epoxy Systems create perfectly smooth surfaces ideal for cleanrooms, laboratories, and food processing facilities. These systems typically range from 1/8" to 1/4" thick and can incorporate antimicrobial additives. They're perfect where hygiene and easy cleaning are priorities.

Mortar Epoxy Systems combine epoxy resin with graded aggregates to create extremely durable floors capable of withstanding forklift traffic and heavy impact. These systems, ranging from 1/4" to 1/2" thick, are the go-to choice for warehouses, manufacturing plants, and loading docks.

Epoxy Terrazzo Systems blend decorative aggregates with clear epoxy to create aesthetically pleasing floors suitable for retail spaces, showrooms, and commercial areas that need both beauty and performance.

Conductive and Static-Dissipative Systems incorporate specialized additives to control static electricity buildup. Electronics manufacturing, ammunition storage, and pharmaceutical production rely on these systems to prevent dangerous static discharge.

Chemical-Resistant Systems use specialized novolac epoxy resins and provide protection against aggressive chemicals, acids, and solvents. Chemical processing plants, battery manufacturing, and plating operations depend on these high-performance systems.

Each system type can be customized with specific aggregates, colors, and additives to match exact application requirements. Professional epoxy floor contractors evaluate factors like traffic patterns, chemical exposure, temperature ranges, and aesthetic requirements to recommend the optimal system configuration.

Unmatched Benefits That Make Epoxy the Smart Choice

Exceptional Durability Against Heavy Traffic and Impact

Industrial epoxy flooring delivers unmatched strength that stands up to the most demanding environments. Picture a warehouse floor handling thousands of pounds of machinery rolling across it daily, or a manufacturing facility where heavy equipment operates around the clock. Regular concrete simply can't handle this punishment without showing serious wear and tear within months.

Epoxy floor coating creates a protective barrier that's significantly harder than standard concrete. When properly installed, these floors can withstand loads exceeding 10,000 PSI without cracking or chipping. The secret lies in the chemical bond formed between the epoxy resin and the concrete substrate, creating a unified surface that distributes weight evenly across the entire floor.

Drop a wrench, and watch it bounce off without leaving a mark. Heavy forklift traffic that would normally create ruts and damage becomes routine daily operation. This incredible impact resistance means your floors maintain their professional appearance even in the busiest facilities. Many epoxy flooring services report installations lasting 15-20 years in high-traffic industrial settings without requiring replacement.

Chemical Resistance That Protects Your Investment

Manufacturing environments expose floors to harsh chemicals that would destroy ordinary surfaces within weeks. Epoxy flooring systems provide exceptional protection against acids, alkalis, oils, solvents, and other aggressive substances commonly found in industrial operations.

Different epoxy formulations offer varying levels of chemical resistance:

| Chemical Type | Standard Epoxy | High-Performance Epoxy | Specialized Coatings |

|---|---|---|---|

| Mild Acids | Excellent | Excellent | Excellent |

| Strong Acids | Good | Excellent | Superior |

| Petroleum Products | Excellent | Excellent | Excellent |

| Industrial Solvents | Good | Excellent | Superior |

| Caustic Solutions | Fair | Good | Excellent |

Automotive shops dealing with motor oils and brake fluids find epoxy floors incredibly valuable. Chemical processing plants rely on specialized epoxy systems to prevent costly floor replacement and contamination issues. The non-porous surface prevents chemicals from seeping into the concrete, protecting the structural integrity of your building foundation.

Professional epoxy floor contractors can recommend specific formulations based on your facility's unique chemical exposure risks. This customization ensures maximum protection and extends the life of your flooring investment significantly.

Easy Maintenance That Saves Time and Money

Traditional concrete floors require constant attention - sweeping, scrubbing, and dealing with dust that never seems to go away. Industrial epoxy flooring transforms maintenance from a daily struggle into a simple routine that anyone can handle.

The smooth, seamless surface eliminates the porous nature of concrete that traps dirt, oil, and bacteria. Daily maintenance involves basic sweeping and occasional mopping with standard cleaning solutions. Spills wipe up easily without staining or penetrating the surface.

Regular maintenance routine includes:

-

Daily sweeping with soft-bristle brooms

-

Weekly damp mopping with mild detergent

-

Monthly deep cleaning with mechanical scrubbers

-

Quarterly inspection for minor touch-ups

Labor costs drop dramatically compared to maintaining untreated concrete. Facilities typically see 60-70% reduction in cleaning time and supply costs. The bright, reflective surface also reduces lighting requirements, cutting electricity bills in large facilities.

Unlike carpet or tile systems that harbor bacteria and require specialized cleaning equipment, epoxy floors maintain hygiene standards with minimal effort. Food processing facilities particularly benefit from this easy-clean surface that meets strict sanitation requirements.

Enhanced Safety Through Slip-Resistant and Non-Toxic Properties

Worker safety becomes significantly better with properly installed epoxy flooring systems. The surface can be customized with various textures and additives to create optimal traction levels for different work environments.

Anti-slip aggregates mixed into the topcoat provide excellent grip even when surfaces are wet. Machine shops where cutting fluids create slippery conditions benefit from textured epoxy that maintains traction without being abrasive to foot traffic. Loading dock areas exposed to rain and snow become much safer with slip-resistant epoxy systems.

Bright color options improve visibility and can be used to mark safety zones, walkways, and equipment areas. Yellow striping for caution zones and green for safe walkways become permanent parts of the floor rather than tape that peels and requires constant replacement.

Modern epoxy formulations meet strict VOC (Volatile Organic Compound) regulations and contain no harmful substances that could affect indoor air quality. Workers can operate in these environments without concerns about toxic fumes or off-gassing that older flooring systems produced. Many epoxy flooring services now offer zero-VOC options for facilities with sensitive operations or strict environmental requirements.

The seamless nature eliminates trip hazards from loose tiles or uneven concrete sections. Emergency cleanup becomes faster and more effective since spills can't penetrate the surface or hide in cracks where they might create ongoing safety risks.

Choosing the Right Epoxy System for Your Needs

Self-Leveling Epoxy for Smooth, Seamless Surfaces

Self-leveling epoxy delivers exactly what its name promises—a perfectly flat, mirror-like finish that eliminates surface imperfections and creates an ultra-smooth working environment. This epoxy floor coating flows across your concrete substrate like liquid glass, automatically finding and filling in small cracks, divots, and uneven spots that would otherwise create maintenance headaches down the road.

The magic happens in the chemistry. Self-leveling formulations contain special flow agents and viscosity modifiers that allow the material to spread evenly across large areas without leaving roller marks, brush strokes, or thickness variations. Most applications range from 1/8 to 1/4 inch thick, providing substantial coverage while maintaining that seamless appearance that makes cleaning and maintenance incredibly simple.

Industrial epoxy flooring professionals recommend self-leveling systems for facilities where hygiene is paramount—pharmaceutical manufacturing, food processing plants, laboratories, and healthcare facilities. The absence of joints, seams, or surface texture means bacteria and contaminants have nowhere to hide. Regular mopping with standard cleaning solutions keeps these floors spotless.

Installation requires careful surface preparation and temperature control. The concrete must be properly profiled and completely dry, with ambient temperatures typically between 60-85°F for optimal flow characteristics. Professional epoxy flooring services use specialized gauge rakes and spiked rollers to ensure uniform thickness across the entire application area.

Mortar Epoxy for Maximum Impact and Chemical Resistance

When your facility faces the toughest industrial challenges, mortar epoxy systems step up to deliver unmatched durability and protection. These heavy-duty epoxy floor coatings incorporate specially graded aggregates—typically quartz sand or decorative chips—directly into the epoxy matrix, creating a composite material that can withstand forklift traffic, dropped tools, chemical spills, and thermal shock.

The aggregate content usually ranges from 40-80% by volume, depending on the specific performance requirements. Higher aggregate loading provides greater impact resistance but may sacrifice some chemical resistance, while lower loadings offer superior chemical protection with adequate mechanical strength for most applications.

Mortar epoxy excels in manufacturing environments, automotive shops, aircraft hangars, and chemical processing facilities. The system typically applies at 1/4 to 1/2 inch thickness, allowing it to bridge minor substrate cracks and provide a substantial protective barrier. The textured surface offers excellent slip resistance even when wet, making it ideal for areas where workers handle liquids or cleaning operations occur regularly.

Epoxy floor contractors often recommend broadcast application techniques for mortar systems. This involves applying a base coat of epoxy, broadcasting the aggregate to refusal (complete coverage), then applying additional epoxy coats to encapsulate the aggregate and create the final surface profile. Some applications include a final seal coat of clear epoxy to enhance chemical resistance and ease of cleaning.

Flake Epoxy for Decorative Appeal with Performance

Flake epoxy systems prove that industrial flooring doesn't have to sacrifice aesthetics for performance. These decorative epoxy flooring options combine the durability and chemical resistance of traditional industrial coatings with attractive color patterns that enhance any workspace appearance.

The decorative flakes—available in countless color combinations, sizes, and patterns—are broadcast into a wet epoxy base coat, then sealed with clear topcoats. Full-broadcast applications completely hide the underlying concrete with a dense layer of flakes, while partial-broadcast systems allow some of the base color to show through for more subtle effects.

Beyond appearance, flake systems offer practical advantages. The textured surface created by the flakes provides excellent slip resistance without being difficult to clean. The random pattern helps hide dirt, scuff marks, and minor wear that would be obvious on solid-color floors. Many facilities choose flake systems for customer-facing areas like showrooms, retail spaces, or office areas where appearance matters but durability remains essential.

Popular flake combinations include earth tones for automotive facilities, bright primary colors for recreational areas, and subtle gray blends for professional environments. Custom color matching is available for facilities wanting to incorporate specific corporate colors or design themes.

Anti-Static Epoxy for Sensitive Electronic Environments

Electronic manufacturing, data centers, telecommunications facilities, and laboratories handling sensitive equipment require specialized epoxy flooring that prevents static electricity buildup. Anti-static epoxy systems incorporate conductive materials that safely dissipate electrical charges, protecting both equipment and personnel from static discharge damage.

These specialized coatings contain carbon black, metallic particles, or conductive polymers that create controlled electrical pathways to ground. The surface resistance typically measures between 10^4 to 10^6 ohms, providing the ideal balance between conductivity and safety. Regular testing with specialized meters ensures the flooring maintains proper electrical properties throughout its service life.

Installation requires additional steps beyond standard industrial epoxy flooring applications. The concrete substrate often needs special conductive primers, and copper grounding strips must be properly installed and connected to the facility's electrical grounding system. Epoxy floor contractors specializing in these applications understand the critical importance of maintaining electrical continuity throughout the installation process.

Anti-static epoxy comes in various aesthetic options, from utilitarian gray to decorative patterns, proving that technical performance doesn't require sacrificing appearance. Regular maintenance involves using only approved cleaning products that won't interfere with the conductive properties, and periodic resistance testing ensures ongoing compliance with industry standards.

Professional Installation Process for Optimal Results

Critical Surface Preparation That Ensures Long-Term Adhesion

Surface preparation makes or breaks any epoxy flooring project. Professional epoxy floor contractors know that rushing this phase leads to costly failures down the road. The concrete substrate must be mechanically sound, clean, and properly profiled to create the ideal bonding surface for your epoxy floor coating.

Diamond grinding stands as the gold standard for surface preparation. This process removes the top layer of concrete, exposing fresh aggregate and creating the perfect profile for maximum adhesion. Shot blasting offers another excellent option, particularly for larger areas where speed matters. Both methods create the necessary surface texture that allows the epoxy to mechanically bond with the concrete.

Moisture testing can't be overlooked. Concrete naturally contains moisture that can cause epoxy failure if levels exceed manufacturer specifications. Professional installers use calcium chloride tests or relative humidity probes to measure moisture content accurately. Any reading above 3 pounds per 1,000 square feet per 24 hours typically requires moisture mitigation before proceeding.

Oil and chemical contamination present unique challenges that demand specialized treatment. Degreasers alone won't cut it for heavy contamination. Steam cleaning, followed by acid etching or specialized concrete cleaners, removes stubborn residues that could prevent proper adhesion. Some situations require grinding contaminated concrete to virgin material.

Crack repair and joint filling must happen before epoxy application. Professional epoxy flooring services assess each crack individually, determining whether simple filling or structural repair is needed. Moving cracks require flexible fillers, while static cracks can accept rigid repair compounds.

Proper Application Techniques for Maximum Performance

Temperature and humidity monitoring starts before the first drop of epoxy hits the floor. Most industrial epoxy flooring systems require substrate temperatures between 60-90°F with relative humidity below 85%. Smart contractors use infrared thermometers to check floor temperature and ensure it stays at least 5°F above the dew point throughout application.

Mixing ratios demand precision that leaves no room for guesswork. Professional installers use digital scales rather than volume measurements, ensuring exact ratios every time. Pre-mixing components separately before combining prevents incomplete reactions that compromise performance. Most systems require 2-3 minutes of thorough mixing using paddle mixers at specific speeds.

Application timing creates a narrow window that professionals navigate expertly. Most epoxy systems provide a 20-45 minute pot life, depending on temperature and formulation. Experienced crews plan their mixing and application schedule to avoid waste while maintaining wet edge consistency across the entire floor.

Roller technique affects both appearance and performance. Professional installers use high-quality phenolic core rollers with specific nap lengths designed for epoxy application. Cross-rolling patterns ensure uniform thickness and eliminate roller marks. Spiked rollers release trapped air bubbles that could create weak spots or surface imperfections.

Curing Time and Environmental Factors That Affect Quality

Temperature control during curing dramatically impacts final performance. Each 18°F temperature increase roughly doubles the cure rate, while cooler temperatures extend curing times significantly. Professional installations often include temporary climate control to maintain optimal conditions throughout the entire curing process.

Humidity management prevents surface defects that can ruin an otherwise perfect installation. High humidity can cause amine blush, creating a waxy surface film that prevents proper adhesion of subsequent coats. Dehumidifiers and proper ventilation maintain ideal conditions during the critical first 24-48 hours.

Foot traffic restrictions protect your investment during the vulnerable curing period. Most epoxy floor coatings accept light foot traffic after 12-24 hours but require 3-7 days before heavy equipment or chemical exposure. Professional contractors provide detailed timelines specific to your chosen system and environmental conditions.

Chemical resistance develops gradually as the epoxy reaches full cure. While basic chemical resistance appears within days, maximum performance often requires 7-14 days of full cure. Understanding these timelines helps facility managers plan operations around installation schedules without compromising the flooring system's long-term durability.

Maximizing Longevity Through Smart Maintenance

Daily Cleaning Protocols That Preserve Your Floor

Your epoxy flooring investment deserves protection through consistent daily care that keeps it looking professional and performing at peak levels. The good news? Daily maintenance doesn't require complicated procedures or expensive equipment.

Start each day with a simple dry sweep using a soft-bristled broom or dust mop to remove loose debris, dirt, and particles that could scratch the surface. For busy industrial facilities, consider using a walk-behind dust mop for larger areas to maintain efficiency.

When spills occur, address them immediately. Epoxy floor coating responds best to prompt cleanup, preventing stains from setting and reducing slip hazards. Use a damp microfiber mop with warm water for most spills, or add a pH-neutral cleaner for stubborn spots. Avoid harsh chemicals like bleach or ammonia, which can compromise the epoxy's protective properties over time.

High-traffic zones need extra attention. Place walk-off mats at entrances to minimize tracked-in dirt and moisture. These simple additions can reduce your daily cleaning time while protecting the floor finish.

For industrial epoxy flooring exposed to oils or chemicals, keep absorbent materials nearby for quick spill response. The faster you clean spills, the less likely they are to penetrate or stain the surface.

Periodic Deep Cleaning for Sustained Performance

Weekly or bi-weekly deep cleaning sessions restore your epoxy flooring to its original luster and remove buildup that daily cleaning might miss. This process doesn't need to be overwhelming - just more thorough than your daily routine.

Mix a commercial degreaser with warm water according to manufacturer specifications. Apply the solution across the floor and allow it to dwell for the recommended time before scrubbing with a soft-bristled brush or floor machine. Pay special attention to corners, joints, and areas around equipment where grime tends to accumulate.

For facilities with heavy machinery, steam cleaning can be particularly effective. The combination of heat and pressure removes embedded dirt and oil residues that standard mopping cannot reach. Schedule these sessions during downtime to avoid disrupting operations.

After deep cleaning, rinse thoroughly with clean water and allow the floor to air dry completely. Proper rinsing prevents cleaner residue from building up and creating a slippery film on the surface.

Early Problem Detection That Prevents Costly Repairs

Regular inspection routines catch small issues before they become expensive problems. Train your maintenance team to spot warning signs during daily cleaning activities.

Look for these key indicators:

-

Scratches or gouges that expose the substrate

-

Bubbling or peeling at edges or high-stress areas

-

Discoloration that might indicate chemical damage

-

Worn spots in high-traffic zones

-

Cracks in the coating or substrate

Document any issues with photos and location notes. This creates a maintenance history that helps track problem areas and guides future prevention strategies.

Temperature fluctuations can cause expansion and contraction issues. Monitor your facility's climate control systems to maintain stable conditions that protect your epoxy flooring investment.

Water infiltration from below can cause serious problems. Check for moisture issues around drains, under equipment, and near exterior walls. Address drainage problems immediately to prevent substrate damage that could require complete floor replacement.

Professional Recoating Schedules for Extended Life

Even the best-maintained epoxy flooring will eventually need professional attention to maintain peak performance. Planning recoating schedules based on actual floor condition rather than arbitrary timelines maximizes your investment.

Most industrial epoxy flooring systems need professional recoating every 5-7 years under normal conditions. Heavy industrial use might require attention every 3-5 years, while lighter commercial applications could extend to 8-10 years with proper care.

Work with qualified epoxy flooring services to assess your specific needs. Professional contractors can evaluate wear patterns, coating thickness, and adhesion quality to recommend the optimal recoating schedule.

Partial recoating of high-wear areas can extend overall floor life cost-effectively. Focus professional attention on traffic lanes, loading areas, and equipment zones while maintaining the rest of the floor through regular cleaning protocols.

Schedule recoating during planned downtime to minimize business disruption. Professional epoxy floor contractors can often complete projects over weekends or during maintenance shutdowns, ensuring your operations resume smoothly with refreshed, high-performance flooring.

Cost Analysis That Proves Epoxy's Value

Initial Investment Versus Long-Term Savings

When evaluating epoxy flooring services in India, many business owners are often surprised by the initial investment. Good-quality industrial epoxy flooring typically ranges from ₹40 to ₹150 per square foot, depending on the type of system, floor preparation, and required thickness. Although this may seem expensive compared to basic concrete paint or sealers, the real value becomes clear when you look at the total cost over 10–20 years.

Traditional flooring options lead to a cycle of frequent repairs and replacements. Normal concrete paint lasts only 1–2 years before peeling. Vinyl tiles often crack under heavy machinery and require patchwork or full replacement every 5–7 years. These recurring costs quickly add up and, in many cases, exceed the initial investment of epoxy flooring.

In contrast, industrial epoxy flooring offers exceptional durability and typically lasts 15–20 years with proper installation and maintenance. This long lifespan results in significant long-term savings:

| Flooring Type | Initial Cost/sq ft | Lifespan (years) | Total 20-Year Cost/sq ft | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Concrete Paint | ₹20 – ₹50 |

|

|

||||||

| Vinyl Tiles |

|

|

| ||||||

| Industrial Epoxy |

|

|

|

The numbers speak clearly - epoxy flooring provides better value despite higher upfront costs. Many epoxy floor contractors offer financing options, making the initial investment more manageable while preserving cash flow for other business priorities.

Reduced Downtime and Maintenance Costs

Production downtime costs industrial facilities thousands of dollars per hour. Traditional flooring failures force unplanned shutdowns for emergency repairs, disrupting schedules and frustrating customers. Epoxy flooring dramatically reduces these costly interruptions through superior durability and predictable maintenance schedules.

Seamless epoxy surfaces resist cracking, chipping, and chemical damage that plague other flooring types. This reliability means fewer surprise repairs and more predictable maintenance budgets. When maintenance is required, epoxy floors can often be spot-repaired without shutting down entire production areas.

Daily cleaning becomes faster and more efficient with epoxy flooring. The smooth, non-porous surface allows for quick mopping and doesn't trap dirt, oils, or chemicals like textured concrete. Many facilities report 30-40% reductions in cleaning time compared to bare concrete floors.

Chemical spills pose serious threats to both worker safety and flooring integrity. Epoxy floor coating systems provide excellent chemical resistance, preventing costly damage from acids, solvents, and other harsh substances. Quick cleanup prevents staining and deterioration that would require expensive repairs or replacement with other flooring types.

Energy Efficiency Benefits That Lower Operating Expenses

The reflective properties of epoxy flooring create surprising energy savings that compound over time. Light-colored epoxy systems reflect 60-90% of available light, compared to just 20-30% for bare concrete. This enhanced light reflection reduces lighting requirements and creates brighter work environments without additional fixtures.

Many facilities report 10-15% reductions in lighting costs after installing reflective epoxy flooring. In large warehouses or manufacturing plants, these savings can amount to thousands of dollars annually. The improved brightness also enhances safety and productivity by reducing eye strain and improving visibility.

Epoxy flooring contributes to better HVAC efficiency through thermal properties. The smooth surface reduces air turbulence compared to rough concrete, allowing heating and cooling systems to work more effectively. Some epoxy systems include thermal barrier properties that help insulate floors, reducing heat transfer and maintaining more consistent indoor temperatures.

Dust reduction provides another hidden energy benefit. Bare concrete floors generate dust particles that clog HVAC filters and reduce system efficiency. Epoxy flooring eliminates this dust source, extending filter life and maintaining optimal airflow. Facilities often experience 20-30% longer intervals between filter changes, reducing both material costs and maintenance labor.

The combination of lighting savings, improved HVAC efficiency, and reduced maintenance creates a powerful financial advantage. These operating expense reductions often offset the initial epoxy flooring investment within 3-5 years, making every subsequent year pure profit.

Epoxy flooring stands out as the clear winner for industrial applications, delivering unmatched durability, chemical resistance, and long-term value that traditional flooring simply can't match. From understanding the different epoxy systems available to working with professionals for proper installation, every step in the process contributes to creating a floor that will serve your facility for decades to come.

The investment in quality epoxy flooring pays for itself through reduced maintenance costs, minimal downtime, and superior performance under the toughest industrial conditions. Don't let outdated flooring hold back your operations – explore epoxy options today and transform your facility with a flooring solution that's built to handle whatever your business demands.

Comments

Post a Comment